Last year the Service Center for Rural Areas (DLR) Rheinlandpfalz (Rhineland-Palatinate) has steamed vineyards for the very first time, in order to research the effects of this soil sterilization method on young vine.

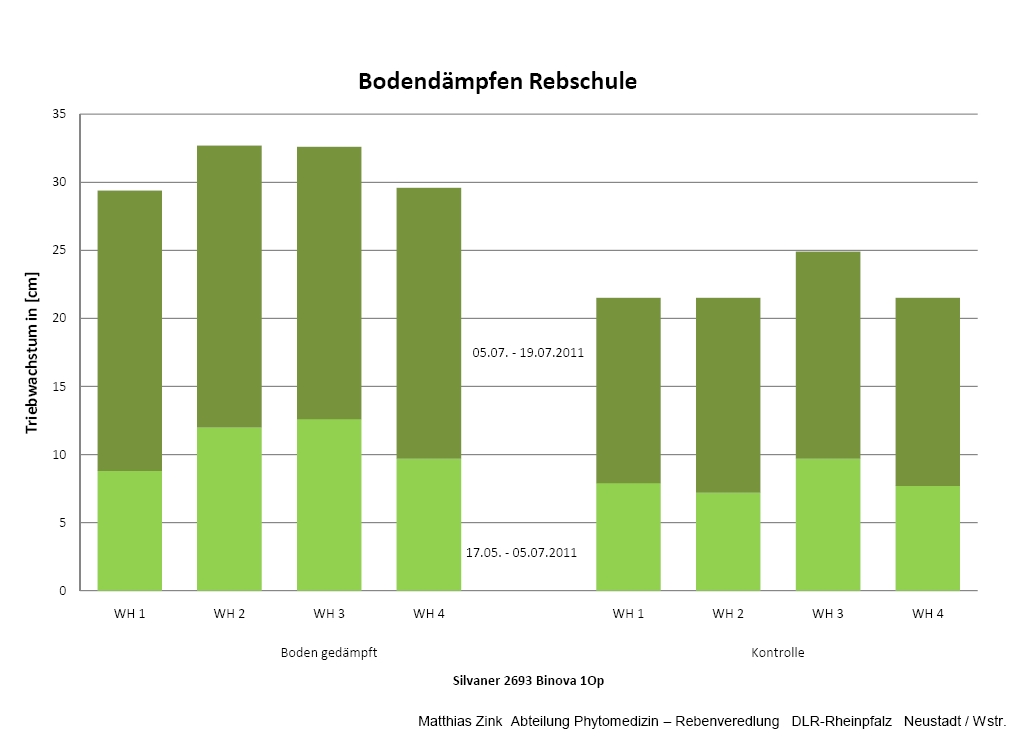

Recently the results were presented. It was shown, that steam significantly increases the growth of plant shoots:

Steaming significantly increases the growth of vine shoots (Source: DLR Rhineland-Palatinate, Schifferstadt)

It remains to be clarified, if hot steam significantly improves the sprouting of vine. In particular where soil is both highly contaminated with diseases (such as fungus, bacteria, nematodes) and highly affected by soil fatigue, steaming could be developed to a profitable sanitation method for vine nurseries.

Under the leadership of Matthias Zink the DLR in Schifferstadt started a research study together with the steaming specialist MSD (Möschle-Seifert-Dämpftechnik – Steaming Technology) this year. Results are expected next year.